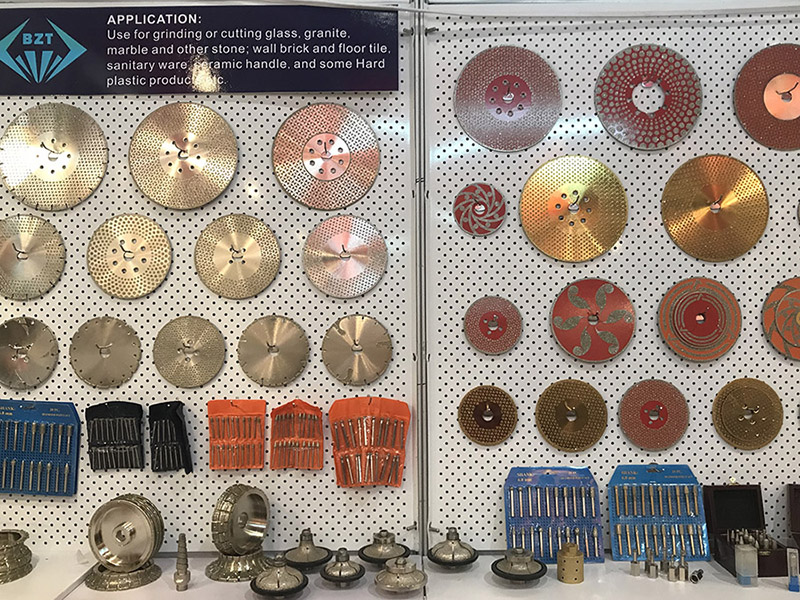

Electroplated diamond grinding and cutting disc:

Electroplated diamond grinding and cutting disc is used for cutting and grinding glass, jade, agate, emerald, vitrified tiles, microlite tiles, granite, marble, ceramic tile, stainless steel, abrasive steel etc. Both dry use and wet use are acceptable, wet use has better effect.

Long working life, high hardness, good wear resistance and impact resistance are its main advantages. Multi-layer plated craft characteristic determines its self-sharpness function. It features no chipping, small slotting and high sharpness.

Electroplated grinding and cutting disc has wide diamond grit, from 30 to 2000. 30-100 grit is suitable for cutting. Grit above 120 is suitable for polishing. Smaller grit disc is sharper, but surface smoothness is not very good. On the contrary, larger grit disc is blunter, and surface smoothness is good. Abrasive disc with grit on the back has grinding and cutting two functions.

The base material of electroplated grinding and cutting disc is special steel, which has good flexibility and high binding degree with diamond grit. Titanize, nickelage and original are common surface treatment methods.